NTT Adhesives FAQs

FAQs for NTT Adhesives

Q1 Can I purchase NTT adhesive products and how do I get a quote?

A1 Yes, you can purchase NTT products that are being shipped anywhere in North or South America from FiberSource by obtaining a quote by clicking here.

Q2 Where can I get SDS and Curing/Storage manual?

A2 FiberSource can provide all documents and information that you may need when you receive your quote by contacting us.

Sample

Q3 Can I get NTT samples?

A3 NTT does not provide free samples, but you can purchase small quantities, 5g or 10g, for evaluation.

Contact us to learn more.

Delivery format

Q4 What types of containers are used?

A4 Most NTT products are custom-made to order in brown, UV-blocking glass jars.

Q5 Can I purchase NTT adhesives in syringes? Is it possible to place NTT adhesive in a specific syringe that I would provide?

A5 If NTT adhesives are packaged in syringes, the risk is not high, and the chances are it will be fine, but there is always a risk of leakage and NTT-AT cannot be held responsibility if it does happen. Therefore, it is not recommended for us to request this method of packaging. However, if you are willing to take this risk, contact us to arrange for your order to be packaged in Musashi Engineering syringes (PN PSY-EU). These syringes have no scale indication type (i.e., 3ml, 5ml or 10ml). You would basically request how many grams you want in each syringe, making sure the total amount of grams you are ordering is correct. For example, if you are ordering 5 grams of product, you can “re-package” your order into five 1-gram syringes. You can also “re-package” into four 1.25-gram syringes and various other combinations.

You also have the option of providing NTT with syringes of your choice. You would have to ship the empty syringes to NTT in Japan in order to request this option. Contact FiberSource for more information on this option.

IMPORTANT NOTE: To reiterate, if you decide to have your order packaged in syringes, you are taking the risk of leakage occurring. If leaking does occur, NTT-AT nor FiberSource is responsible for any leakage.

Q6 Are NTT adhesive products already de-gassed?

A6 NTT adhesives are de-gassed before packing and shipping so you can use them without de-gassing. However, if you decide to de-gass again, we recommend a centrifuge or a vacuum. We do not have a specific time or parameters that are recommended; therefore, please follow the instructions recommended by an equipment manufacturer.

Preprocessing

Q7 Do I need any type of surface treatment before applying NTT adhesive?

A7 Please make sure there is no debris or oil on the surface. If you clean the surface with an organic solvent, evaporation of the solvent may lower the temperature and attract water on the surface (condensation). Therefore, please air-dry using an air-gun or alike before applying the NTT adhesive. Also, depending on the material of your surface, a coupling agent, ozone treatment, or plasma treatment can help to improve the strength of the NTT adhesive.

Curing

Q8 Are NTT adhesives UV-curable? Or thermal-curable?

A8 Standard NTT adhesive products on the website and in brochures are UV-curable. During UV-curing, strains may be created. After UV curing, a thermal treatment is recommended to remove strains to enhance long term reliability. For more details about curing mechanism differences between epoxies and acrylates, please contact NTT’s technical support by clicking here.

Q9 There are "standard curing conditions" written in the product manual. What are standard curing conditions? Can I modify curing parameters?

A9 The recommended curing parameters written in a product manual are created based on the minimum amount of UV irradiation strength and time length needed to cure adhesive. To minimize the strains created during UV-curing, we recommend a slow curing with minimum irradiation strength. If you need to shorten the curing time, please refer to Q11.

Q10 What kind of ultraviolet curing device is best to use to cure UV-curing NTT adhesives?

A10 Please use an ultraviolet curing device with a high-pressure mercury lamp or metal halide lamp, capable of radiating 365nm wavelength. You can also use LED with a peak at 365 nm. However, LED has a few peaks where the wavelength's total energy generated is lower than with broad range lamps. Thus, to have the same amount of total energy, you will need to adjust the exposure time or irradiation strength with LED. You will need approximately 3 times longer the time (or 3 times stronger the irradiation strength) with LED compared to high pressure mercury lamps or metal halide lamps.

Q11 Can I shorten the curing time?

A11 Slow curing is recommended to avoid strains and stresses, but you can shorten the curing time by gearing up UV irradiation strength. As long as NTT adhesives receive the same amount of total energy, they will cure. For example, you can cut the curing time by half if you double the UV dosage. However, fast curing tends to create strains & stresses which may potentially lead to cracks and delamination. If curing time must be shortened, please (at the least) start with the recommended UV dosage written in the manual. Then you can apply what is referred to as “step curing,” which is where you gear up the UV irradiation strength step by step. Refer to Q16 for more details about "step curing."

Q12 Do I need to apply heat? What is the recommended way to apply heat?

A12 It is recommended to apply heat after UV curing to improve long-term durability. If you want to check on bonding ability only, you don’t need a heat treatment. During UV curing, strains will occur, and the strains can lower the adhesion strength (“delamination”) during a long-term reliability test. To ease the strains, it is best to apply the heat at Tg temperature or above; however if you cannot apply heat at Tg temperature, please refer to the temperature mentioned in the manual. If you do not have a manual, please contact us.

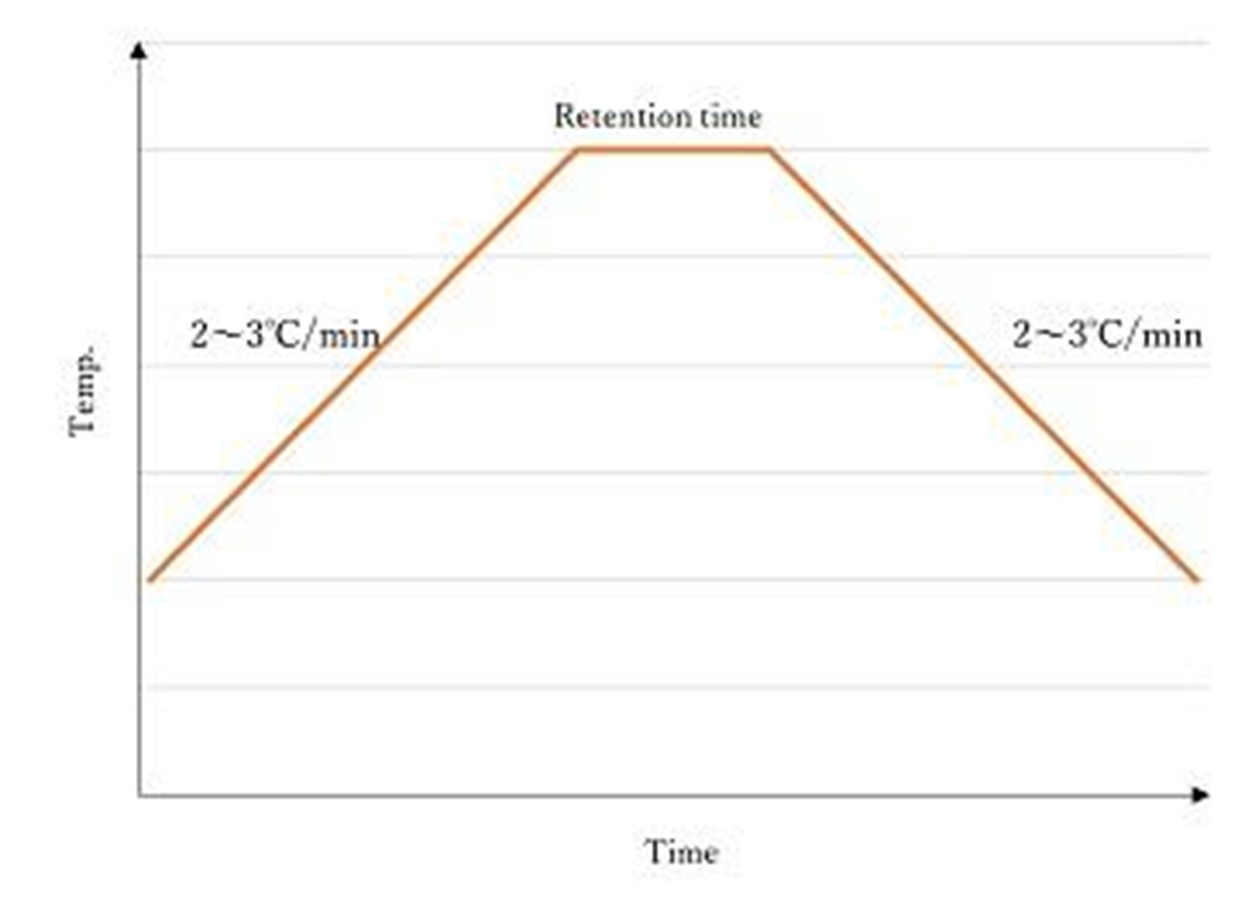

When you apply heat, please increase the temperature slowly to avoid a rapid change. After the heating process, please bring down the temperature slowly. It is ideal to increase and decrease the temperature by 2°C to 3°C per minute. Please see the recommended temperature curve below. If you really need to shorten the cooling down time, please wait until (at the very least) it reaches 40°C before taking it out of the oven. However, you should NOT increase the rate of temperature change when you are cooling down after the heating process. It is ideal to bring the temperature down slowly to room temperature before removing the part from the oven. If you really need to shorten the cooling down time, please at least wait until it reaches 40°C, before taking it out from the oven.

Temperature Profile:

Q13 I have shadowed areas where UV light does not reach. What can I do?

A13 Shadowed area(s) remain uncured which may cause delamination. Please irradiate UV lights from multiple angles to ensure UV light reaches everywhere on the adhesive. For epoxies, if your shadowed area is very small, the curing effect may reach the shadowed area(s) and to the heat treatment after UV curing. This can also help to cure the small, shadowed area(s) which is referred to as “dark curing.” Please note that “dark curing” does not apply to acrylate adhesives. Please refer to Q14 for more details.

Q14 What is the mechanism of UV curing?

A14 Epoxies and acrylate cure differently. Epoxies cure by "cationic polymerization." When epoxy receives UV light, organic acids are generated from the photo-initiator which starts the curing process. Even after UV exposure stops, the organic acids remain and continue curing some un-cured parts of the epoxy. Applying heat after UV exposure helps it as well. On the other hand, acrylates are cured by "radical polymerization." When acrylate receives UV light, radicals are generated from the photoinitiator which starts the curing process. When you turn off UV light, radicals are no longer generated and curing stops all at once. Note: Radicals react with oxygen. Surfaces of acrylate exposed to the air may not cure. For more details about oxygen inhibition, please refer to Q15.

Q15 I cannot sure acrylate adhesives well or it remains wet or tacky. What is causing this under-curing? How do I cure acrylate adhesives?

A15 If an acrylate adhesive is exposed to air during UV curing, oxygen in the air inhibits the curing process, thus making the surfaces which are exposed to air not cure. The inside of the acrylate will cure since it is not exposed to air. After UV curing, you may wipe the wetness on the surface with organic solvents. It is also recommended that you cure in a nitrogen environment to avoid oxygen inhibition. NTT also offers epoxy adhesives which do not have oxygen inhibition.

Q16 How do I use the step-curing process to shorten curing time?

A16 Adhesives will cure as long as they receive the same amount of total energy from UV light. For example, when the recommended curing condition is 100mW/cm2 for 5 minutes, the total energy is also 100mW/cm2 x 300 seconds = 30,000mJ. An example of the 5-step curing process to achieve 30,000mJ shortening the curing time from 5 minutes to 2 minutes is as follows:

Step 1; 100mW/cm2 x 45 sec (4,500mJ)

Step 2; 250mW/cm2 x 30 sec (7,500mJ)

Step 3; 350mW/cm2 x 20 sec (7,000mJ)

Step 4: 400mW/cm2 x 15 sec (6,000mJ)

Step 5: 500mW/cm2 x 10 sec (5,000mJ)

Total energy 30,000mJ

Q17 I have finished the curing process, but I cannot tell whether the adhesive is full cured or not. How do I know if the adhesive is fully cured?

A17 After you finish adhering parts, if you move the parts and do not see any misalignment and the adhesive is not “jelly like,” we can safely say it is fully cured. Also, if you can dispense a drop of adhesive on glass, cure it, then poke it with a needle where the needle does not penetrate all the way to the glass, it is fully cured. Another way to know if adhesive is cured or not is to check if you are getting enough adhesion strength or enough hardness.

NOTE: If you cure acrylate adhesive in the air, the surface does NOT cure and remains wet due to “oxygen inhibition.” You may mistakenly believe that the problem is with the adhesive; but actually the problem is that oxygen has inhibited the curing process. The inside of the acrylate which his not exposed to air will be cured.

Features

Q18 Does refractive index have wavelength dependency?

A18 Yes. When you look at the data sheet, please check the refractive index of the adhesive with the specific wavelength that you are using. Products are equipped to measure wavelengths at Sodium D-line(589 nm), 633nm, 830nm, 1300nm, and 1550 nm. FiberSource also offers adhesive products with customizable refractive index. NTT also offers adhesive products with customizable refractive index. If you would like to request a quote for a custom refractive index, please make sure to let us know the wavelength that you use.

Q19 Do you have reliability test data for high temperature or high humidity?

A19 For our standard adhesive products in our line-up, there is heat and humidity test data (121°C/100%) and heat-cycle test data (-40°C ~ 80°C) is available. Please contact NTT Customer Support for more details.

Q20 I have a high-heat process (approximately 260°C). Can adhesives tolerate this?

A20 It depends on the adhesive type and how you use it in your design. Several adhesive products that have higher tolerances to high heat and create cured film samples are used. These were tested at a high temperature (5 minutes on a hot plate preheated to 260°C). Refractive index, adhesion strength, and transparency were measured for changes before and after the 260°C process. You can see the test result from here. (PDF 220 KB).

Warranty

Q21 How long is the shelf life for NTT products? How should I store NTT product(s)?

A21 NTT products have a shelf life of 3 months. You are able to open a bottle, use it, close the bottle, and the shelf life will still be 3 months. Each product has different storage requirements. Please refer to the product manual which will be included in the shipment of your product or during the process of quoting. If you do not have the manual or storage requirements, please contact us.

Q22 Am I able to extend the shelf life longer than 3 months?

A22 After the expiration date, NTT-AT nor FiberSource is not able to guarantee the shelf life of the product past this date. You would solely be responsible for taking the risk of using the product. For storing adhesive(s) at a low temperature in a fridge or freezer, please read here for more details. (PDF 184 KB).

Q23 Can I extend the shelf life if I store the product in a fridge or freezer?

A23 There is the possibility of an extension of quality if the product is stored at a lower temperature; however, if you open it cold, the adhesive may attract and absorb humidity (condensation). NTT highly recommends storing their adhesives at the conditions noted in their respective manuals or on NTT’s Storage Requirements list.